Artificial intelligence (AI) is poised to transition from being a trendy concept to a driving force that reshapes entire industries. Manufacturing, one of the most dynamic sectors, is set to undergo significant changes.

Challenges Facing Modern Manufacturing

Manufacturers today face relentless pressure to produce high-quality products at faster speeds while maintaining cost efficiency. Simultaneously, they must navigate a maze of complex regulations and compliance standards.

In this demanding landscape, speed and adaptability are critical. Companies must rapidly innovate, gather feedback, and fine-tune products to meet the diverse needs of a competitive market. Success often hinges on reducing the time it takes to move from concept to launch.

AI offers the tools to tackle these challenges head-on. By streamlining workflows and optimizing processes, AI empowers manufacturers to innovate faster and scale operations with precision.

How AI is Transforming Manufacturing

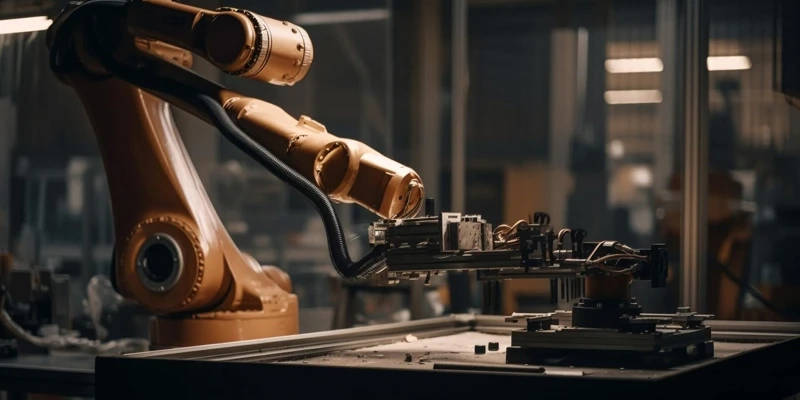

AI brings profound changes to manufacturing by automating repetitive tasks, accelerating critical processes, and enabling teams to focus on strategic, high-value work. Key areas of transformation include:

Simplifying Compliance

Regulatory requirements often vary between regions and industries, creating complexity. AI reduces this burden by analyzing regulations, tracking updates, and ensuring compliance throughout development and production.

Optimizing Design Processes

Model-Based Systems Engineering (MBSE) has long been a cornerstone of product design, helping identify constraints early. AI amplifies MBSE by enabling multi-domain simulations and asynchronous problem-solving across the product lifecycle, unlocking innovative solutions that might otherwise be overlooked.

Speeding Up Simulations

Simulations are essential for testing safety and performance, especially in sectors like automotive and aerospace. AI automates this process, making real-time adjustments to parameters and delivering instant feedback. By identifying potential design flaws or compliance issues, AI accelerates development while ensuring accuracy.

Streamlining Validation

Product validation is critical yet time-intensive, particularly for complex designs. AI automates this stage, analyzing customer preferences and market trends to optimize configurations. This ensures alignment with market demands, boosts efficiency, and enhances profitability.

Strategic Steps for AI Integration

To unlock the full potential of AI in manufacturing, organizations should focus on:

- Building a Unified Digital Thread: Seamlessly connecting data and processes across the lifecycle ensures AI delivers reliable, actionable insights.

- Encouraging Employee Collaboration: Successful AI adoption requires changes in workflows and mindsets. Training employees and fostering collaboration between humans and AI tools will maximize results.

- Prioritizing Scalability: AI solutions must be adaptable and scalable, integrating with existing systems to provide long-term value.

- Ensuring Robust Data Security: Since AI relies on extensive data, protecting sensitive information and ensuring regulatory compliance are essential to maintaining trust.

The Future of AI in Manufacturing

AI adoption will vary by industry, with some prioritizing regulatory compliance and others focusing on innovation. Over time, AI will become deeply embedded in workflows, often used intuitively. This integration will drive unprecedented levels of manufacturing innovation, enabling faster production of superior products.

Organizations that embrace AI with a strategic focus on scalability, collaboration, and security will lead the charge in redefining manufacturing excellence.