Customer

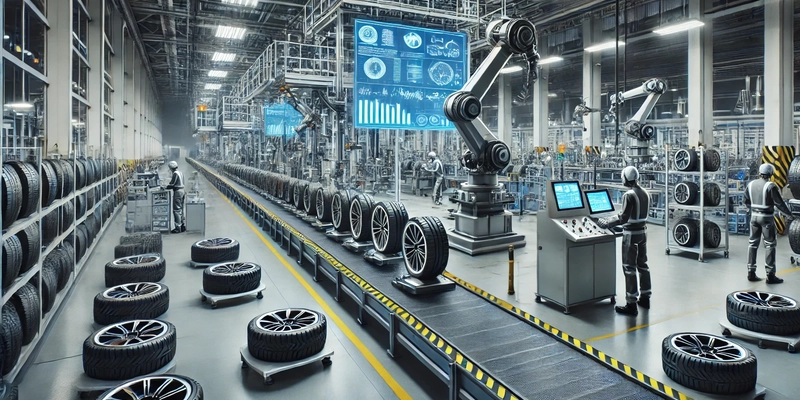

As one of the top 25 tire manufacturers globally, JK Tyre produces over 35 million tires annually, operating across 100 countries with 12 state-of-the-art plants. Their products cater to a wide range of vehicles, from passenger cars to heavy-duty trucks. With such a massive operation, JK Tyre understands the importance of staying ahead in innovation to remain competitive in an evolving industry.

When it came to improving efficiency and quality in their manufacturing processes, JK Tyre didn’t just look for a quick fix—they aimed for a full-scale digital transformation. Enter Altizon, a trusted partner in industrial IoT solutions, to help them rethink their operations from the ground up.

Challenges

Tire manufacturing is a high-stakes process with many moving parts—literally. From mixing rubber compounds to curing finished products, every step needs to run like clockwork. However, JK Tyre faced a few pressing challenges:

- Data silos: Critical production data from different machines and processes wasn’t talking to each other. This made it tough to see the big picture.

- Unpredictable downtime: Machine failures led to delays and unplanned maintenance, eating into productivity and profits.

- Quality gaps: Ensuring consistent quality required more robust tools for analyzing what worked—and what didn’t—on the shop floor.

- Energy waste: High energy use and consumables costs begged for better tracking and optimization.

- Traceability issues: Tracking a product’s journey through the manufacturing lifecycle wasn't always easy, which complicated quality assurance.

JK Tyre needed a modern, scalable IoT solution to connect their machines, streamline operations, and give them real-time insights into what’s happening on the ground.

Altizon’s Answer: A Smart Manufacturing System

Altizon delivered a powerful IoT solution tailor-made for JK Tyre’s complex needs. Using their Datonis IoT suite, they built a connected ecosystem that transformed the company’s manufacturing processes.

Here’s how it worked:

- Datonis Edge: Think of this as the brain at the factory level. It processes machine data locally to ensure operations keep running smoothly, even when network issues arise.

- IoT Data Lake: All machine and production data is collected and stored in one place, making it easier to analyze trends and identify opportunities for improvement.

- Datonis Digital Factory: This platform brings advanced analytics and AI into the mix, helping monitor, measure, and predict outcomes with user-friendly apps.

- ERP Integration: By linking manufacturing data with JK Tyre’s enterprise systems, Altizon ensured seamless production tracking and better inventory control.

Results

- Quality assurance got smarter

Instead of chasing issues after they happened, JK Tyre started identifying patterns that led to quality problems. Statistical analysis and machine data correlations helped pinpoint root causes, ensuring better and more consistent output.

- Preventive maintenance became the norm

Altizon’s tools enabled JK Tyre to monitor machine health in real time. Predictive analytics flagged potential failures before they could cause downtime, saving time and money.

- Energy efficiency improved

Tracking energy consumption revealed inefficiencies that were otherwise invisible. With these insights, the team optimized energy use and cut costs without sacrificing performance.

- Productivity took a leap

With real-time insights into line rates, losses, and performance, JK Tyre’s teams could make informed decisions to keep operations running smoothly. The result? Fewer bottlenecks and higher output.

- Full product traceability

Every tire’s journey—from raw materials to the finished product—was now fully traceable. This made it easier to track quality issues back to their source and maintain rigorous standards.

- Automatic production bookings

Thanks to IT/OT integration, production data flowed straight into the ERP system. This automated approach eliminated manual errors and improved inventory management.

What’s Next for JK Tyre?

After a successful deployment, JK Tyre is rolling out Altizon’s solution to additional plants. The system has become their go-to platform for tracking KPIs and driving continuous improvement.

As Mr. Anil Makkar, JK Tyre’s Manufacturing Director, puts it:

"We are already scaling Altizon’s solution to our second plant and look forward to scaling further as well as using the platform as the single source of truth for monitoring our operational KPIs and continuous improvement initiatives."

For manufacturers looking to modernize, JK Tyre’s journey shows how IoT can bridge the gap between traditional processes and a smarter, more connected future. With a system that keeps everything running smoothly—from the factory floor to the ERP dashboard—they’ve set a new standard for innovation in tire manufacturing.

IoT isn’t just about data - it’s about transforming how industries work. JK Tyre’s success story proves that the right technology, combined with a clear vision, can drive real change.