Challenges in Managing the Return of Vehicle Parts

Encory GmbH, a joint venture between BMW Group and the ALBA Group, recognized the complexity in managing the return of vehicle parts for remanufacturing. The process required a streamlined, internationally accessible platform to manage returns efficiently across various locations. The challenge was ensuring that dealers and warehouses could follow a consistent, regulated process, improving speed-to-market and international availability. Efficient parts management is critical not only for automakers but also for contributing to sustainability by enabling circular economy practices. Without such systems, managing returns would be inefficient, increasing waste and reducing the potential for remanufacturing.

The Solution: Cloud-Based Encory Dealer Frontend

To address these challenges, Encory developed the Dealer Frontend, a cloud-based web application built on the Microsoft Azure platform. This platform supports BMW dealers and warehouse locations globally, enabling the return of parts in a regulated remanufacturing process. The system was developed using an agile project approach with short development cycles, allowing for fast implementation alongside the company's evolving business processes. By integrating usability principles into its design, the system was intuitive for users, minimizing the need for extensive training and adapting based on user feedback. This approach enhances operational efficiency and ensures that the parts remanufacturing process is aligned with sustainability goals.

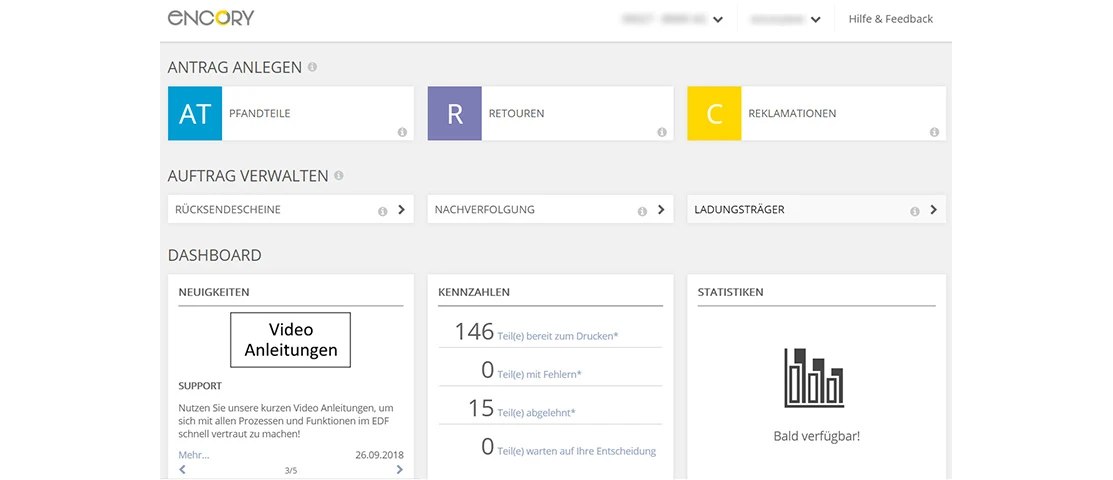

IoT Encory Dashboard example

Impact: Agile Implementation and International Expansion

The agile development strategy enabled Encory to roll out the platform quickly. The system was initially launched in Spain and Portugal, then expanded to larger markets such as Germany and France. By leveraging cloud technology, Encory was able to overcome the limitations of physical infrastructure, ensuring global availability. This successful implementation lays the foundation for future rollouts into additional international markets, supporting continuous growth and efficiency in the parts remanufacturing process.

The introduction of such IoT solutions holds significant value for the entire automotive industry and beyond. By streamlining parts returns and remanufacturing, Encory helps reduce waste, improve resource use, and contribute to the circular economy. As more industries embrace sustainable practices, the scalability of this IoT platform is crucial in meeting global environmental and operational challenges, enhancing both industry competitiveness and sustainability.